There’s no shortage of challenges facing meat and poultry processors each day. Servicing debt, keeping equipment operating, hiring and training qualified workers, handling byproducts, and dealing with demanding customers keep processors awake at night.

The biggest threats to a processor’s business are often unseen. Salmonella, E. coli O157:H7, and listeria are only three pathogens that can cause costly recalls or, worse yet, sickness and death. Lately, news reports have been peppered with stories of problems resulting from meat and poultry produced in large facilities and contaminated with these pathogens.

No processor is too tiny to encounter a catastrophe from these microscopic organisms. Pathogens are only part of the food safety risk. Foreign objects are introduced into a product during processing, and improper identification of allergens can make customers sick and lead to expensive product recalls.

Since the pandemic, more and more people are turning to smaller meat and poultry companies as a trusted source of safe, healthy food. We must earn that trust every day.

It starts with a solid set of Good Manufacturing Practices (GMP) and Sanitation Standard Operating Procedures (SSOP). The foundation is a thorough Hazardous Analysis and Critical Control Point (HACCP) plan.

HACCP plan development can seem like a frustrating, expensive task that must be completed before getting a Grant of Inspection (GOI) from the USDA or the state Department of Agriculture. Too often, it’s seen as a box to be checked off once completed.

However, a good HACCP plan should be considered a type of insurance that is at least as important as the policy protecting a business from fire, tornadoes, or other catastrophes. And, unlike an insurance policy, a HACCP plan isn’t meant to be locked away in a filing cabinet.

A good HACCP plan identifies critical control points within an operation, establishes a monitoring system, and identifies corrective action procedures to be implemented. The monitoring and corrective action producers can help identify and resolve food safety issues before the product leaves the facility.

Product recalls are costly and can threaten a business's financial stability. They often occur after reports of sickness or death from consuming the contaminated products, and no one wants to take that risk.

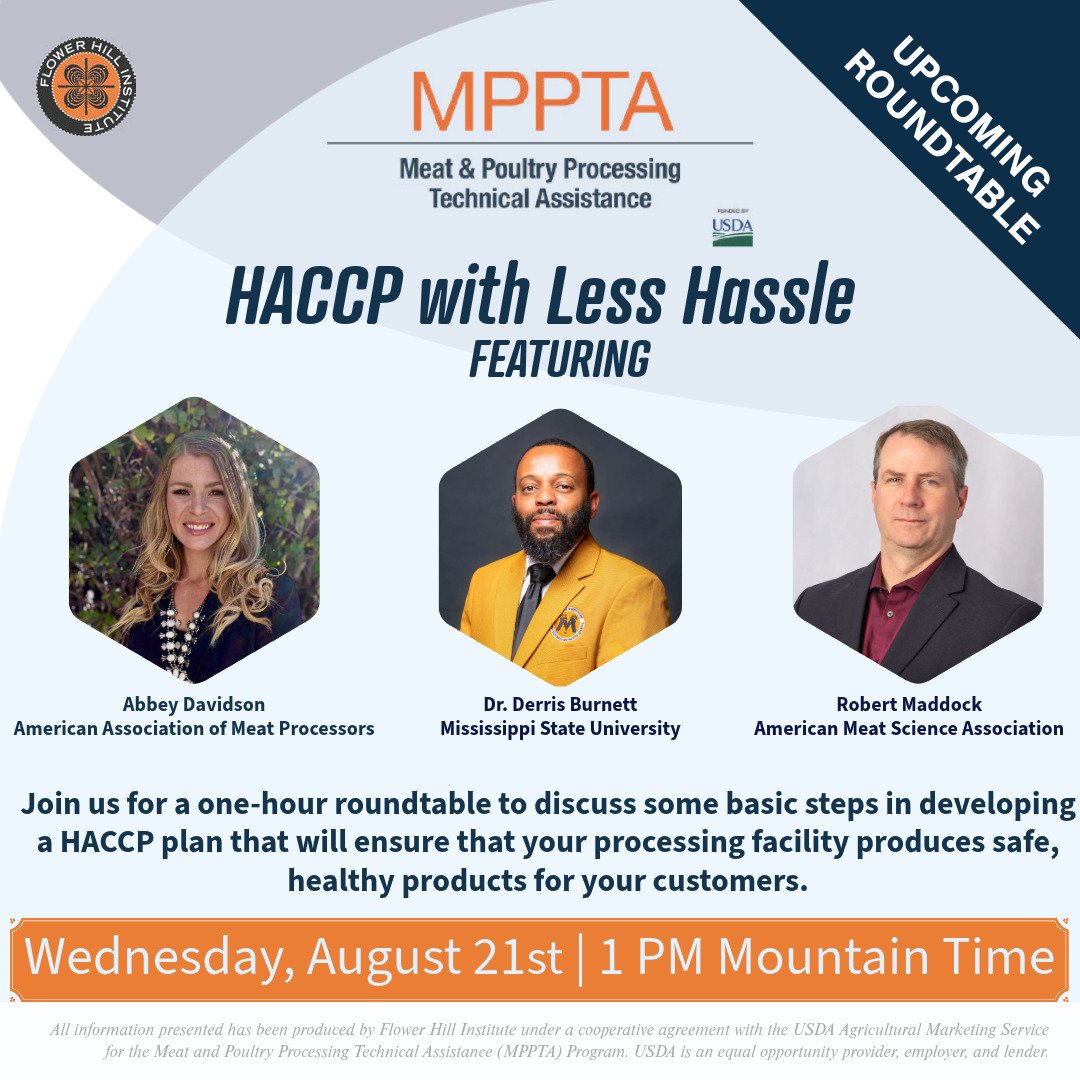

The Meat and Poultry Processing Technical Assistance (MPPTA) program has many resources available to assist processors in developing a thorough HACCP plan. Three of those experts, Dr. Robert Maddock of the American Meat Science Association, Dr. Derris Burnett from Tuskegee University, and Abbey Davidson from the American Association of Meat Processors, joined Flower Hill Institute Regional Directors Chris Roper and Dave Carter on August 21st, for a one-hour online roundtable discussion on HACCP with Less Hassle.

To view a recording of this online roundtable, click here. This one-hour session can help ensure that you are providing your customers with safe meat and poultry products and protecting your business's economic viability.